Custom Solutions For Track Maintance

JG100LT Seigong 10 tons track railway sleeper replacement machine, designed for narrow space and geological fragile section. Construction restrictions on bridge car avoidance holes and steep slopes in mountainous areas; Integrated high-precision hydraulic pillow system, single operation can replace 6-10 sleepers per hour, synchronous completion of ballast backfilling compaction, compared with manual operation efficiency increased by 250%, labor costs reduced by 60%.

Item No :

JG100LTOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

yellowShipping Port :

xiamenLead Time :

15-45daysWeight :

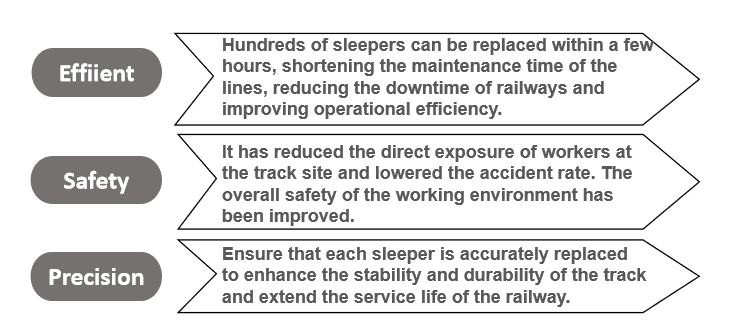

10000kgHundreds of sleepers can be replaced within a few hours, shortening the maintenance time of the lines, reducing the downtime of railways and improving operational efficiency.It has reduced the direct exposure of workers at the track site and lowered the accident rate. The overall safety of the working environment has been improved.Ensure that each sleeper is accurately replaced to enhance the stability and durability of the track and extend the service life of the railway.

|

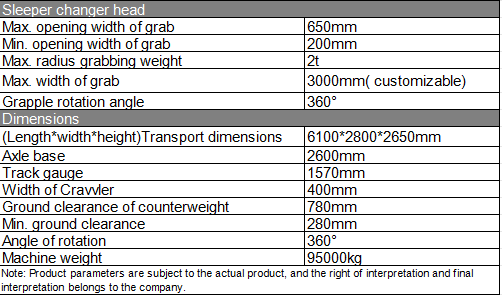

Sleeper changer head |

|

|

Max. opening width of grab |

650mm |

|

Min. opening width of grab |

200mm |

|

Max. radius grabbing weight |

2t |

|

Max.width of grab |

3000mm(customizable) |

|

Grapple rotation angle |

360° |

|

Dimensions |

|

|

(Length*width*height)Transport dimensions |

6100*2800*2650mm |

|

Axle base |

2600mm |

|

Track gauge |

1570mm |

|

Width of Cravvler |

400mm |

|

Ground clearance of counterweight |

780mm |

|

Min.ground clearance |

280mm |

|

Angle of rotation |

360° |

|

Machine weight |

95000kg |

|

Note: Product parameters are subject to the actual product,and the right of interpretation and final interpretation belongs tothe company. |

|

Product Overview

JG100LT Railway Sleeper Replacement Machine Track Maintenance Equipment

JG100LT Specially tailored for narrow tunnels, steep slopes and geo-sensitive sections. The design of ultra-narrow articulated chassis breaks through the space limit and easily deals with low tunnel roof and sharp curve section. The intelligent pressure feedback pillow grasp system ensures that sleepers are replaced with zero damage and high precision, and the ballast leveling is realized synchronously.

Product Advantages

Technical Specifications

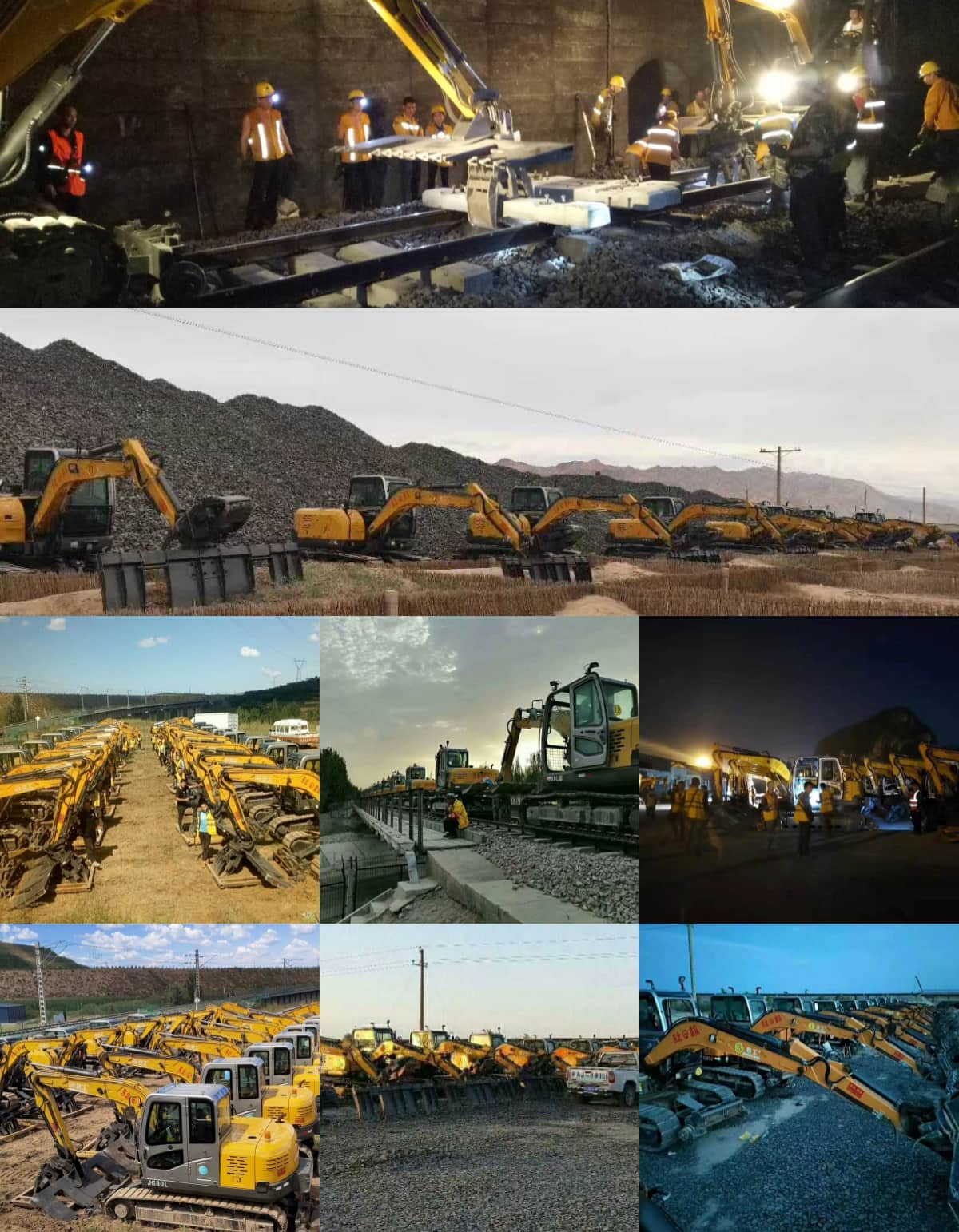

Application scenarios

Global Exhibition

In response to the demands of customers from different regions, the company participates in internationally renowned industry exhibitions every year. Our products are exported to over 60 countries and regions in Central Asia, Southeast Asia, the Middle East, South America, Africa, Oceania and so on. The annual export volume reaches more than 1,500 units and we enjoy a high reputation in overseas markets. Every appearance showcases the brand's global influence. We join hands with our partners to win the future together!

About Us

Quanzhou Jingong Machinery Equipment Co., Ltd. is equipped with various imported large-scale processing equipment, professional technical developers and outstanding management talents. As a global construction machinery manufacturing enterprise integrating R&D, production, sales and service, it provides high-performance and highly reliable construction machinery equipment and intelligent solutions for customers worldwide. The annual sales exceed 30 to 50 million US dollars, and the annual production of excavators can reach about 2,000 to 3,000 units.

Credential

The company has passed the ISO9001 quality management system certification and the national intellectual property certification, and holds nearly a hundred patent certificates including invention patents, design patents and utility model patents. It has been awarded titles such as "Well-known Domestic Trademark" and "National High-tech Enterprise", and has received numerous honors. It has simultaneously won multiple international and domestic invention gold awards and has the right to export independently.

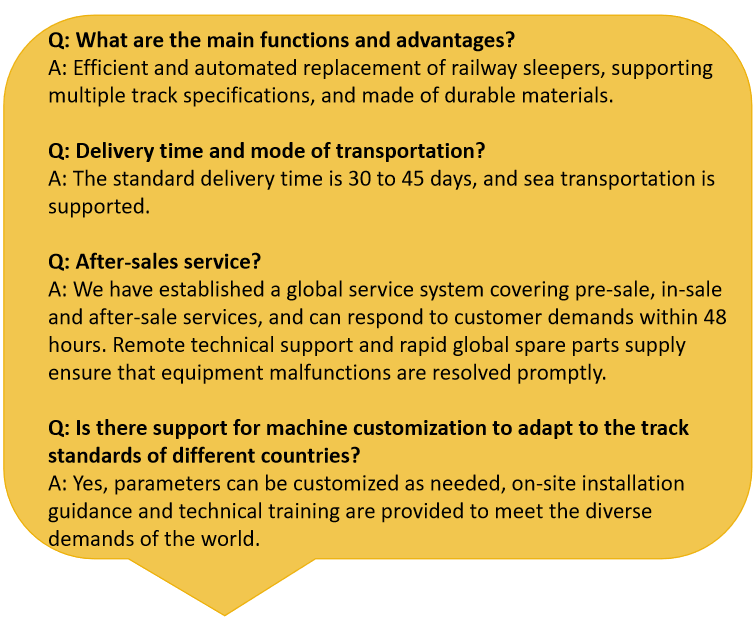

Q&A