Custom Solutions For Track Maintance

JG150S Heavy-duty Double-Head Track Roller Tamping Machine - Used for Railway Maintenance - Ballast Compactor

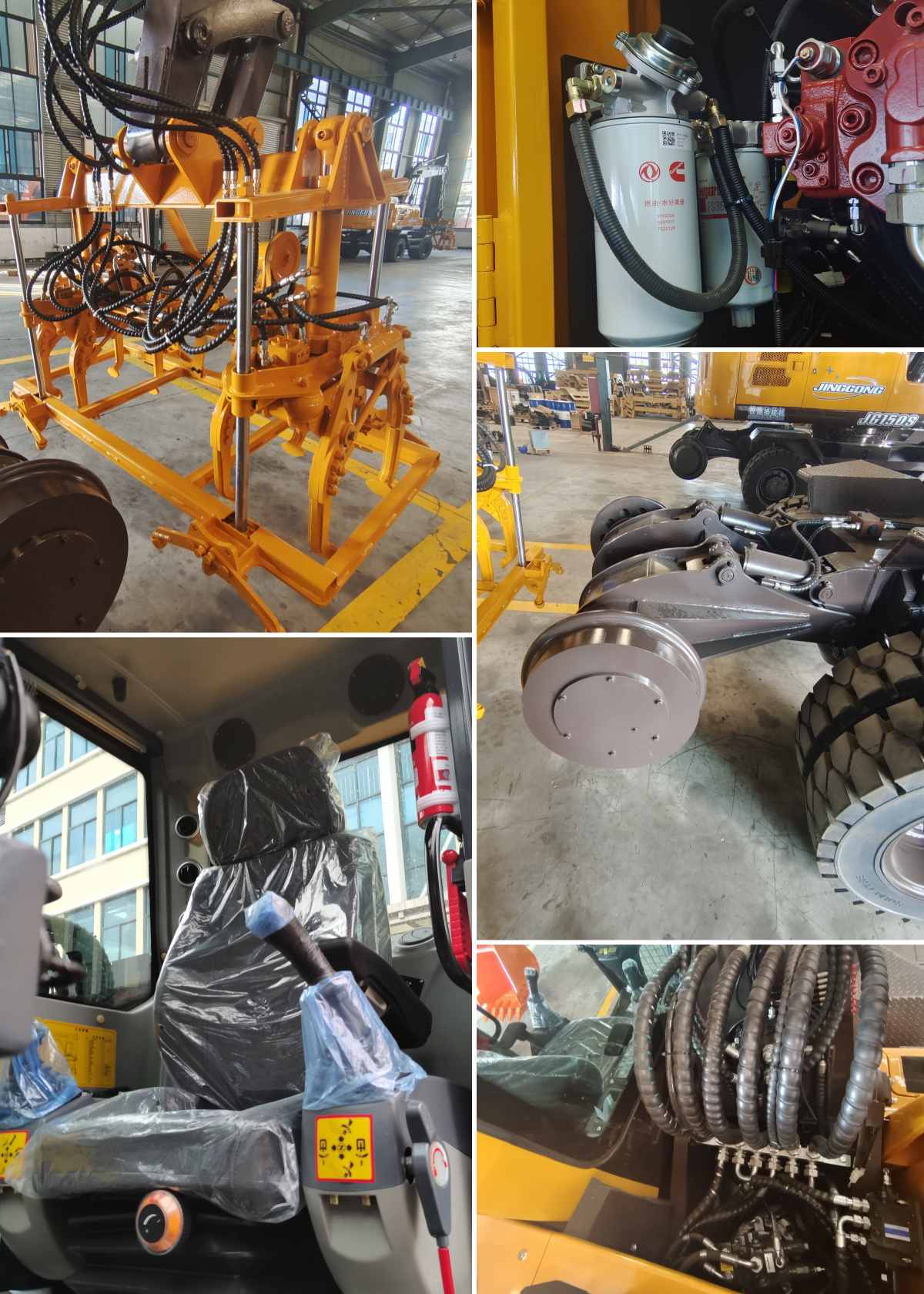

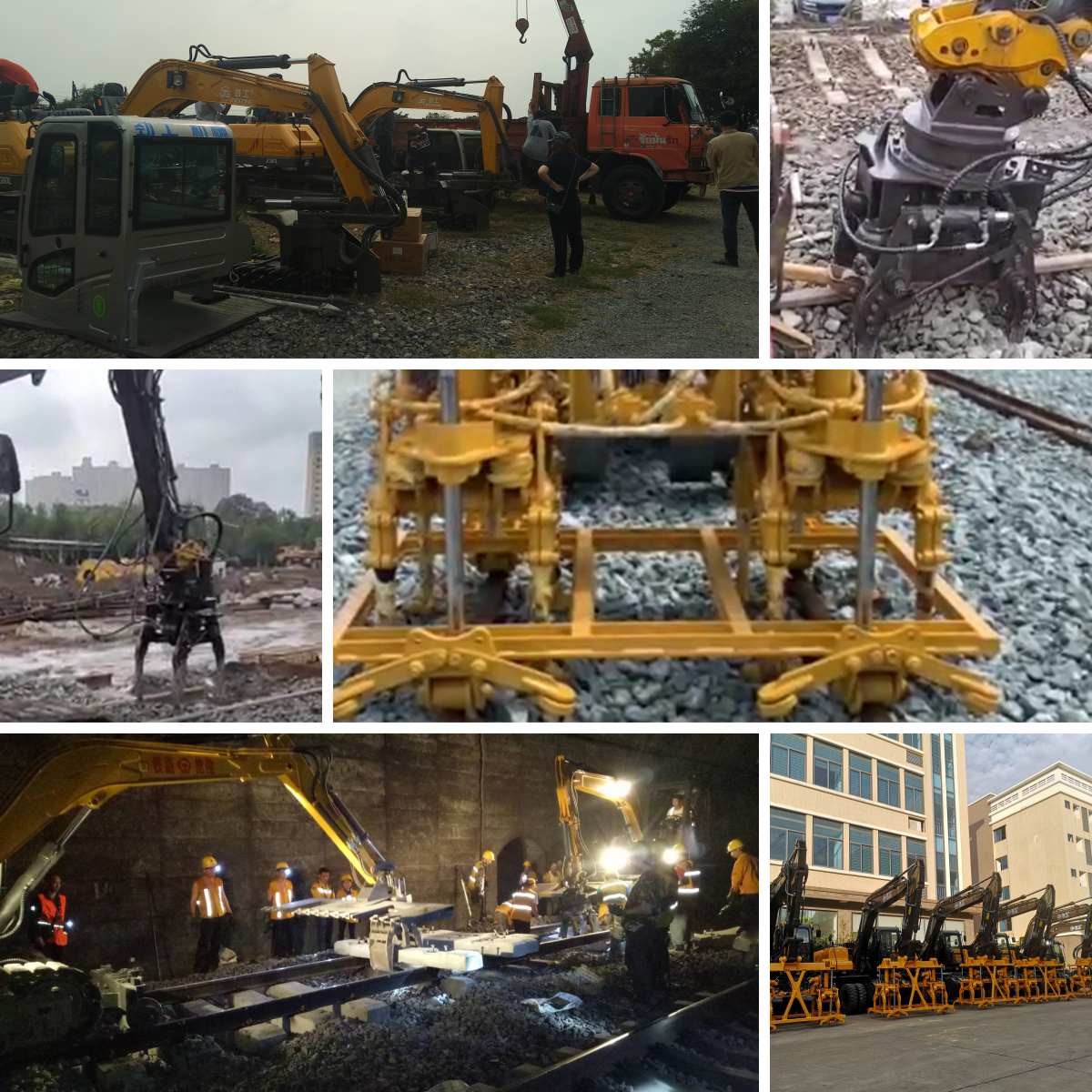

JG150S is a high-performance multi-functional construction machine designed for modern railway track construction and maintenance. It integrates the functions of stamping, digging, track positioning and so on. It is suitable for laying, maintenance and repair of high-speed railway, general railway, subway and special track. The equipment adopts modular double-head design, carries intelligent control system, is compatible with all-weather complex working conditions, and is the core equipment to improve the efficiency of railway maintenance.

Item No :

JG150SOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

yellowShipping Port :

xiamenLead Time :

15-45daysWeight :

15000kgEfficiency,Railway tamping machines adopt automated tamping technology to significantly shorten track maintenance time and ensure that large-scale railway projects are completed on schedule. Accuracy,Realize the millimeter-level error control of ballast tamping, effectively prevent the risk of track deformation, settlement or derailing. Improve the stability of train operation, but also reduce the accident rate. Durability,The railway tamper uses wear-resistant materials and modular design to extend the life of the equipment, while reducing maintenance frequency and labor costs.

|

Range of operation of Hirail Machine |

|

|

Boom length |

4200mm |

|

Arm length |

2000mm |

|

Max. radius of Ballast Tamping |

≥6450mm |

|

Back-end radius of gyration |

2250mm |

|

Specification Of Tamping Head(4Legs) |

|

|

Max.opening size of tamper head |

560×600(mm) customizable |

|

Min.opening size of tamper head |

180×600(mm) customizable |

|

Vibration Frequency |

35-63HZ |

|

Tamping Depth |

≥90mm |

|

Working efficiency |

≥120pcs/h |

|

Dimensions of Hirail Machine |

|

|

(Length*width*height)Transport Dimensions |

7600*2500*3040mm |

|

Axle base |

2750mm |

|

Wheel Base (front/ rear) |

1900mm |

|

Ground clearance of counterweight |

1280mm |

|

Min ground clearance |

320mm |

|

Tech performance and specification of Hirail Machine |

|

|

Applicable railway gauge |

1435mmcustomizable |

|

Exciting Force |

≥21KN |

|

Rotation angle of Machine |

360° |

|

Machine weight |

15870kg |

|

Engine model |

Cummings |

|

Rated Power |

93KW |

|

Rated Speed |

2200r/min |

|

Hydraulic system working pressure |

32Mpa |

|

Hydranlic system flow |

270L/min |

|

Variable piston pump |

2*63ml/r |

|

Max. Walking speed |

30km/h |

|

Grade Climbing ability |

58%/30° |

|

Full circle swinging time |

5.5s |

|

Fqt Fuel Quantity |

≥6L/h |

|

Capacity Of The Fuel Tank |

200L |

|

Hydraulic Tank Capacity |

200L |

|

Note: The product parameters are based on the actual product, and the right of interpretation and final interpretation belong to the company. |

|

Product Overview

15ton Double Head Railway Tamping Machine Railway Wheeled Excavator

JG150S 15 ton double-headed railway excavator is an intelligent road maintenance equipment integrating track stamping and earth excavation. Through the collaborative operation of the front high-frequency stamping head and the rear multifunctional excavator arm, its rubber tire + track wheel dual mode chassis support, ensuring the stability of frozen soil, subway and other complex scenes. The maintenance efficiency is increased by 50% and the labor cost is saved by 45%.

Product Advantages

Application scenarios

Q&A

Q1: What is the core function of tamper?

A: Precise track adjustment; Ballast compaction: uniform compaction of the gravel layer under the sleeper; Dynamic adjustment

Q2: Can extreme environments be operated stably?

A: full climate hydraulic system; Seismic structure; Fault pre-check:

Q3: What are the advantages over manual work?

A: multi-point synchronous job; Continuous marching construction; Intelligent analysis system

Q4: Is it applicable to tracks from different countries?

A: Modular toolset; Gauge adaptive; Multi-type adaptation

Q5: What are the guarantees for overseas customers?

A: Equipment operation teaching; Global emergency response; Lifelong technical support