Custom Solutions For Track Maintance

JG80LT 8-Ton Multi-Functional Rail Ballast Excavator & Tamper Crawler Tracked Design

Railway ballast tamping crawler is a highly integrated engineering machinery designed for the fine maintenance of railway lines. It breaks through the single limitation of traditional equipment function, the ballast padding, digging and cleaning, material transfer three core functions in one, with compact track chassis to adapt to the complex line environment, significantly improve the track maintenance efficiency and reduce labor costs, is the innovation tool of modern railway maintenance operations.

Item No :

JG80LTOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

yellowShipping Port :

xiamenLead Time :

15-45daysWeight :

8000kgEfficiency,Railway tamping machines adopt automated tamping technology to significantly shorten track maintenance time and ensure that large-scale railway projects are completed on schedule. Accuracy,Realize the millimeter-level error control of ballast tamping, effectively prevent the risk of track deformation, settlement or derailing. Improve the stability of train operation, but also reduce the accident rate. Durability,The railway tamper uses wear-resistant materials and modular design to extend the life of the equipment, while reducing maintenance frequency and labor costs.

|

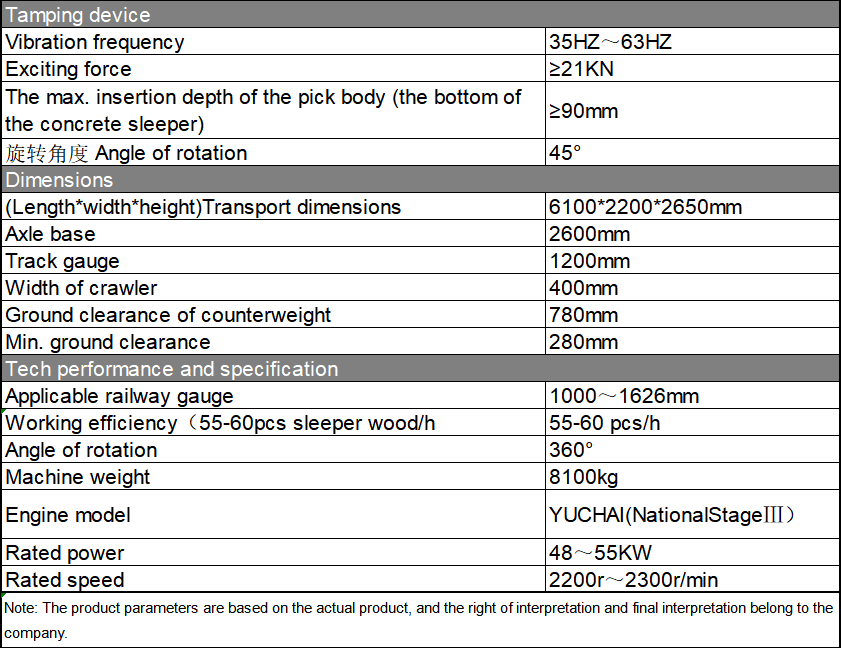

Tamping device |

|

|

Vibration frequency |

35HZ~63HZ |

|

Exciting force |

≥21KN |

|

The max. insertion depth of the pick body (the bottom of the concrete sleeper) |

≥90mm |

|

Angle of rotation |

45° |

|

Dimensions |

|

|

(Length*width*height)Transport dimensions |

6100*2200*2650mm |

|

Axle base |

2600mm |

|

Track gauge |

1200mm |

|

Width of crawler |

400mm |

|

Ground clearance of counterweight |

780mm |

|

Min. ground clearance |

280mm |

|

Tech performance and specification |

|

|

Applicable railway gauge |

1000~1626mm |

|

Working efficiency(55-60pcs sleeper wood/h ) |

55-60 pcs/h |

|

Angle of rotation |

360° |

|

Machine weight |

8100kg |

|

Engine model |

YUCHAI(NationalStageⅢ) |

|

Rated power |

48~55KW |

|

Rated speed |

2200r~2300r/min |

|

Note: The product parameters are based on the actual product, and the right of interpretation and final interpretation belong to the company. |

|

Product Overview

8ton Railway Excavator Railway Ballast Tamping Crawler Machine

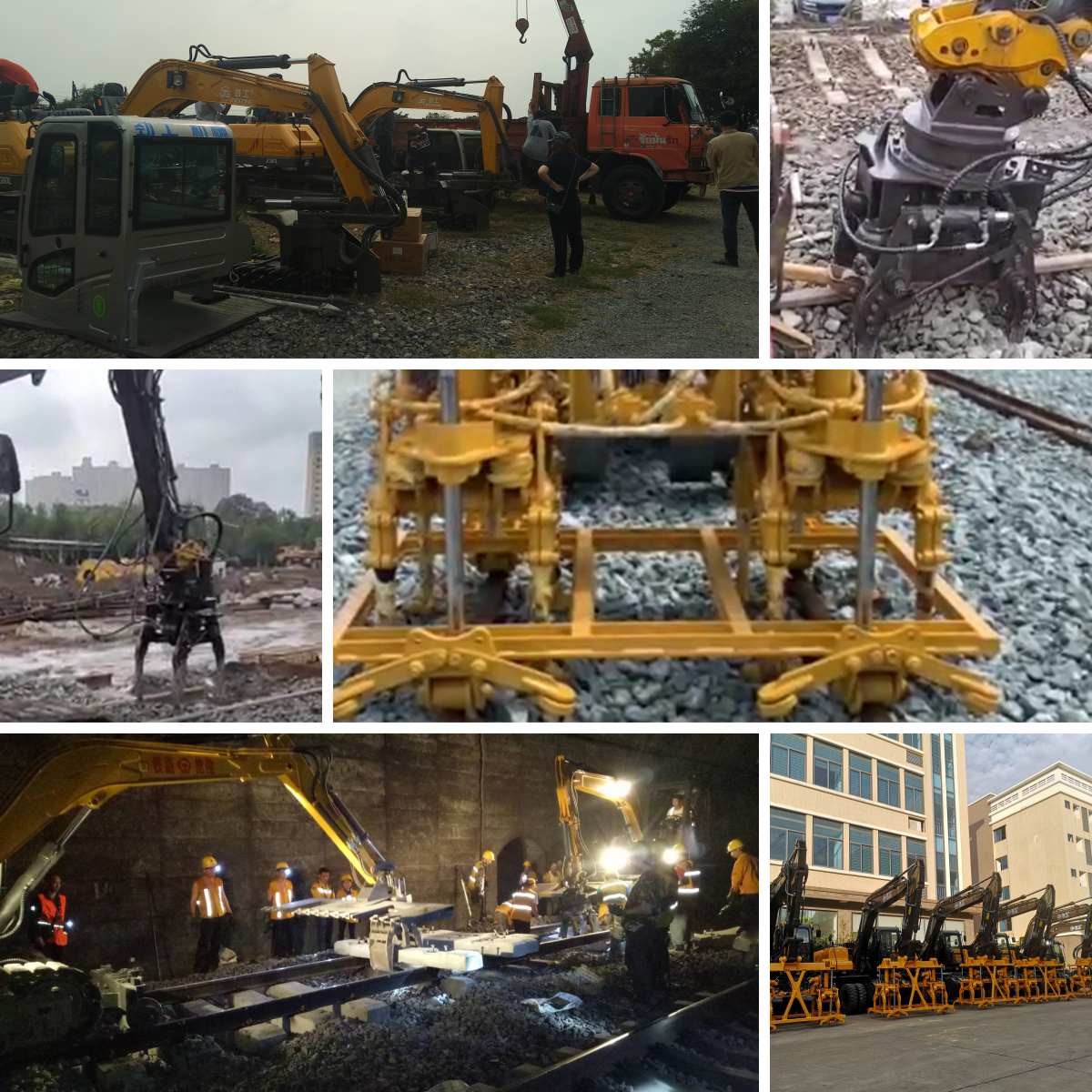

JG80LT 8 tons of railway multi-functional road maintenance machinery with a highly integrated design to reshape the railway bed maintenance standards, deep integration of ballast tamping and excavation cleaning dual-core functions in the compact track platform. In narrow scenes such as mountain railways and tunnel boundaries, a single machine and multiple processes can be seamlessly connected. Relying on reinforced rubber tracks to meet all-weather emergency needs

Product Advantages

Efficiency:Railway tamping machines adopt automated tamping technology to significantly shorten track maintenance time and ensure that large-scale railway projects are completed on schedule.

Accuracy:Realize the millimeter-level error control of ballast tamping, effectively prevent the risk of track deformation, settlement or derailing. Improve the stability of train operation, but also reduce the accident rate.

Durability:The railway tamper uses wear-resistant materials and modular design to extend the life of the equipment, while reducing maintenance frequency and labor costs.

Technical Specifications

Application scenarios

Q&A

Q1: What is the core function of tamper?

A: Precise track adjustment; Ballast compaction: uniform compaction of the gravel layer under the sleeper; Dynamic adjustment

Q2: Can extreme environments be operated stably?

A: full climate hydraulic system; Seismic structure; Fault pre-check:

Q3: What are the advantages over manual work?

A: multi-point synchronous job; Continuous marching construction; Intelligent analysis system

Q4: Is it applicable to tracks from different countries?

A: Modular toolset; Gauge adaptive; Multi-type adaptation

Q5: What are the guarantees for overseas customers?

A: Equipment operation teaching; Global emergency response; Lifelong technical support

The JG180S Wheeled Railway Sleeper Changing Machine Railway Excavator is a revolutionary piece of equipment designed specifically for the railway construction and maintenance industry. With its advanced technology and robust design, it offers unparalleled efficiency and reliability in sleeper changing operations.

Read More

The JG150LT Railway Sleeper Changing Machine, a cutting - edge crawler railway excavator, is a game - changer in the realm of railway maintenance. Engineered to perfection, it offers a comprehensive solution for efficient and effective sleeper replacement operations.The crawler design of the JG150LT provides it with outstanding mobility on railway tracks. It can smoothly navigate through various terrains, including uneven surfaces and curves. This allows the machine to reach every part of the railway network, ensuring that no sleeper replacement task is out of reach. Whether it's a long - distance mainline or a short - stretch siding, the JG150LT can get the job done.

Read More

JG150LT15 ton track railway excavator railway single head tamping machine is a kind of efficient construction machinery designed for railway track maintenance, which integrates track mining and tamping functions in one. The equipment uses 15 tons of heavy chassis and modular structure design, equipped with intelligent hydraulic system and precise positioning module, can quickly complete the track ballast mining, ballast tamping under the pillow and track geometric parameter adjustment and other operations, the single head tamping device through high-frequency vibration and pressure control technology to achieve uniform compaction of the track bed, operating efficiency than traditional equipment increased by more than 30%.

Read More

The JG150LT 15-ton track tamping machine is a reliable support for the precise adjustment and maintenance of railway lines. As a heavy-duty professional equipment, it is specifically designed to efficiently address the geometric deviations of the track (such as gauge, level, and height). With its powerful tamping capability, it can penetrate the ballast layer and quickly complete the compacting of the ballast and the stabilization of the sleepers, significantly enhancing the stability and smoothness of the track structure, and laying a solid foundation for the safe and smooth operation of trains.

Read More

JG150S is a high-performance multi-functional construction machine designed for modern railway track construction and maintenance. It integrates the functions of stamping, digging, track positioning and so on. It is suitable for laying, maintenance and repair of high-speed railway, general railway, subway and special track. The equipment adopts modular double-head design, carries intelligent control system, is compatible with all-weather complex working conditions, and is the core equipment to improve the efficiency of railway maintenance.

Read More

JG100SF ballast cleaning screen machine.Professional track cleaning solution! The integrated efficient screening system can quickly remove dirt and gravel impurities from the road bed, and the treatment capacity is up to 300m³/h. The modular design ADAPTS to the global standard gauge, and the automatic operation reduces the labor investment by 70%, which significantly improves the drainage and stability of the line. It is suitable for maintenance of heavy-duty railway, subway and high-speed line. The corrosion-resistant steel structure ensures the service life of more than 10 years.

Read More

JG120S 12-ton wheeled rail excavator equipped with material leveler is an innovative construction machinery designed for coal leveling. It combines the dual functions of mining and leveling. It uses a 12-ton wheeled chassis to achieve fast switching between road and railway, carrying efficient hydraulic system and intelligent leveling module. It can accurately complete the mining, shaping and surface leveling tasks of coal pile to ensure the uniform distribution of materials and the efficiency of track maintenance. The compact and durable design of the whole machine is suitable for complex working conditions in coal mines, railway freight yards and industrial stations. The operating efficiency is increased by more than 25% compared with traditional equipment, while reducing manual intervention and operating costs. It is an ideal solution for modern material handling and track maintenance.

Read More

JG80LT 8-Ton Railway Ballast Regulator & Hirail Excavator.Specially designed for efficient track maintenance, integrated ballast finishing and rail overhaul functions. The 8-ton working capacity is adapted to the global standard gauge, and the hydraulic system accurately controls the distribution of ballast to strengthen the stability of the track foundation. Multi-joint manipulator to achieve 360° flexible operation, equipped with replaceable fittings, easy to complete slope shaping, sleepers clear ballast and rail positioning. It conforms to ISO safety certification, ADAPTS to complex working conditions such as high temperature and cold, greatly reduces manual maintenance costs, and improves railway operation and maintenance efficiency by more than 30%.

Read More