Custom Solutions For Track Maintance

JG150LT Railway Specialized Excavator Track Maintenance 15-ton Wheeled Shell Loader Excavator

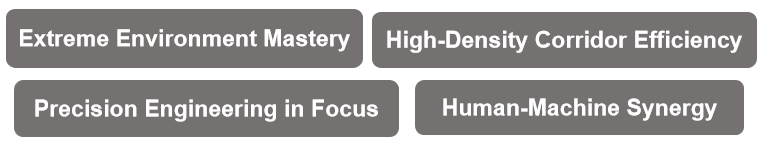

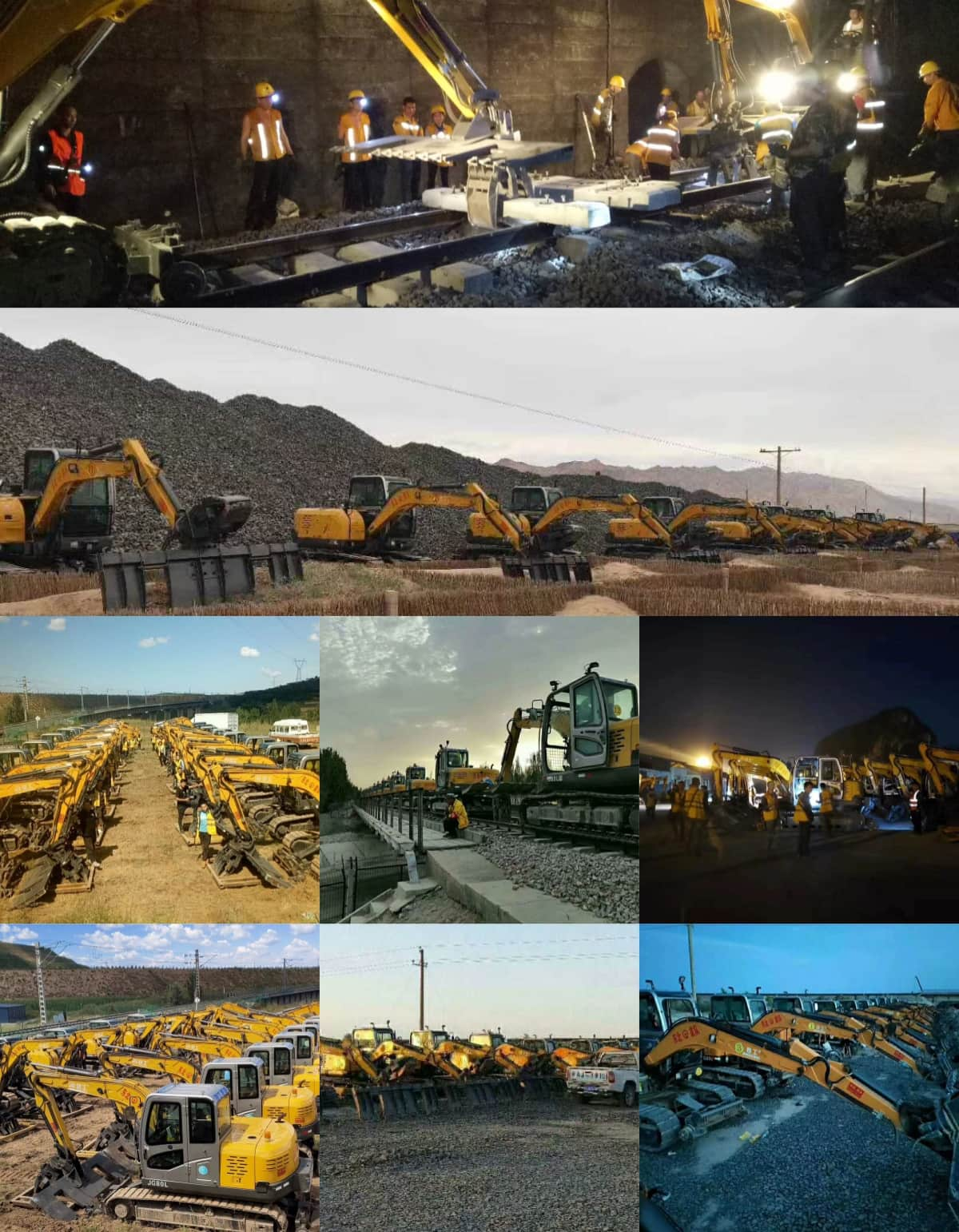

JG150LT is designed for high-load railway infrastructure. Its 15-ton reinforced clam shell grab adopts double cylinder hydraulic drive system, which can accurately clutch giant ballast and tunnel waste rock, and achieve safe and efficient material transfer in the height limit area of electrified railway contact network. Integrated dynamic balance technology of ultra-wide track chassis can effectively reduce the risk of soft soil subgrade settlement; The design of multi-joint boom breaks through the traditional excavation dead Angle, and easily handles the three-dimensional construction scenes such as bridge pier cleaning and deep drainage ditch excavation, becoming a strong weapon for the expansion of multi-track railway.

Item No :

JG150LTOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

yellowShipping Port :

xiamenLead Time :

15-45daysWeight :

15000kgThe crawler-type shell bucket excavator adopts a unique shell bucket design, which enables it to quickly excavate and load soil, gravel, and other materials. It is particularly suitable for railway track laying and ditch excavation tasks. With its crawler chassis, this excavator can flexibly move in the rugged, muddy or narrow areas along the railway line, and easily handle the complex terrain near the tracks. The shell bucket design is flexible. It can handle regular excavation tasks, and can also be used for railway cleaning or material transportation. The versatility of this machine reduces equipment investment costs.

Product Overview

JG150LT 15Ton Railway Excavator Clamshell Bucket

Facing the challenge of global extreme working conditions, the core module is equipped with an intelligent temperature control and dust barrier system to maintain stable output from the equatorial high temperature and humidity to the polar frozen zone. The whole car wire harness is treated with military grade shock proof and waterproof, and the maintenance period is extended by 40%. It provides EPC contractors with "zero downtime" railway construction plan with low carbon emissions in the whole life cycle.

Product Advantages

Application scenarios

Q&A

A: Its crawler design offers excellent stability and off-road mobility. The shell-dump can efficiently excavate hard soil and crushed stones, ensuring reliable operation in rugged terrains such as railway track laying and foundation treatment.

A: The features include the powerful digging and loading capabilities of the shell bucket. The advantages lie in its ability to adapt to various soil types and working conditions, its ease of operation, and its potential to reduce the overall project working hours and labor costs.

A: It is mainly used for digging railway trenches, leveling the roadbed, transporting materials and clearing waste. It provides a one-stop solution for the core excavation requirements in railway construction.

A: With a sturdy structure and standardized components, the design is easy to maintain, resistant to wear and tear, ensuring long-term operation in high-intensity railway projects and reducing downtime.

A: Yes, it has been optimally designed to adapt to various climates and terrain conditions, and is easy to transport and install. It is an ideal choice for international railway projects.