Custom Solutions For Track Maintance

JG180LT 18-ton crawler-type track excavator for efficient sand processing equipment

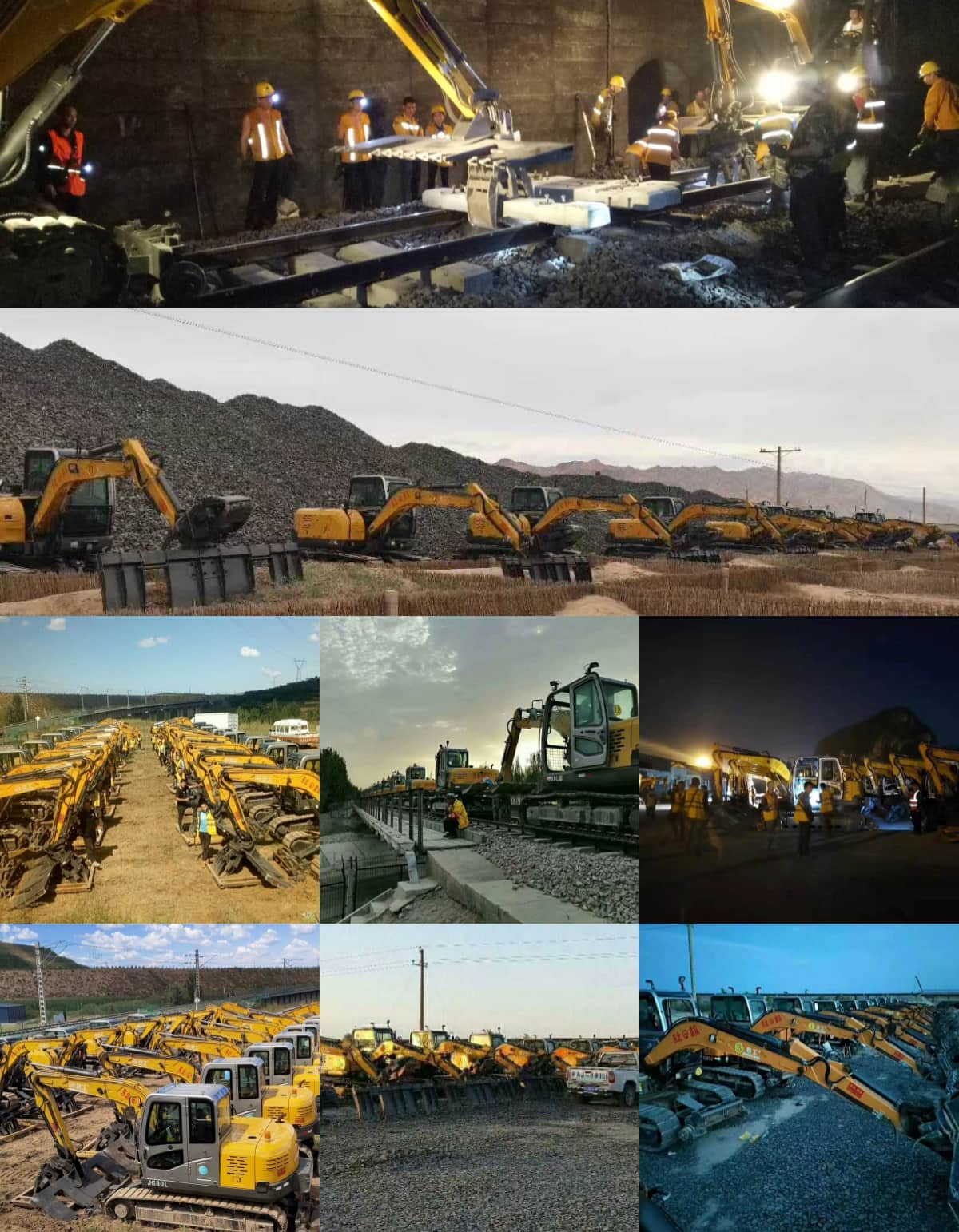

The JG180LT redefines precision in rail infrastructure maintenance as a dedicated 18-ton crawler-type excavator and loader engineered for high-capacity sand and ballast sieving. Mounted directly on railway tracks, this powerhouse eliminates terrain limitations, enabling seamless material processing on active lines without disrupting schedules. Its integrated dual-function design allows operators to swiftly excavate, screen, and reload contaminants-free ballast in a single cycle—dramatically slashing project timelines while ensuring optimal track drainage and stability. Ideal for renewing aging corridors or upgrading high-speed routes, it transforms complex sieving operations into a mobile, self-sufficient workflow that meets the rigorous demands of global rail networks.

Item No :

JG180LTOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

yellowShipping Port :

xiamenLead Time :

15-45daysWeight :

18000kgThrough the integrated sieve bucket design, can quickly screen and separate the ballast, gravel and other materials, significantly improve the efficiency of track maintenance or laying, reduce downtime.Suitable for a variety of railway scenarios, such as track foundation handling, material recovery and cleaning operations, easy to handle narrow Spaces and complex terrain, ensuring that the machine is versatile.The automatic screening process reduces manual intervention, reduces labor intensity and maintenance costs, and extends the life of the equipment, bringing long-term economic benefits.

|

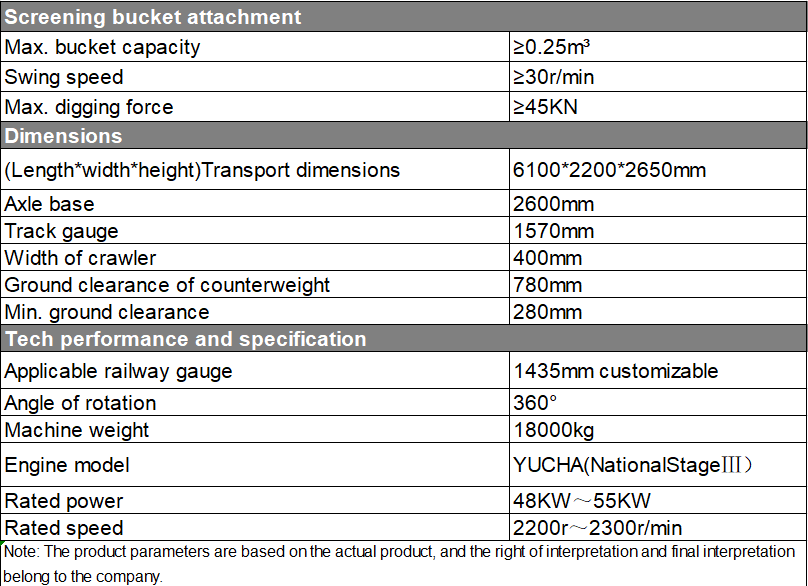

Screening bucket attachment |

|

|

Max. bucket capacity |

≥0.25m³ |

|

Swing speed |

≥30r/min |

|

Max. digging force |

≥45KN |

|

Dimensions |

|

|

(Length*width*height)Transport dimensions |

6100*2200*2650mm |

|

Axle base |

2600mm |

|

Track gauge |

1570mm |

|

Width of crawler |

400mm |

|

Ground clearance of counterweight |

780mm |

|

Min. ground clearance |

280mm |

|

Tech performance and specification |

|

|

Applicable railway gauge |

1435mm customizable |

|

Angle of rotation |

360° |

|

Machine weight |

18000kg |

|

Engine model |

YUCHA(NationalStageⅢ) |

|

Rated power |

48KW~55KW |

|

Rated speed |

2200r~2300r/min |

|

Note: The product parameters are based on the actual product, and the right of interpretation and final interpretation belong to the company. |

|

Product Overview

JG180LT 18-ton railway-mounted sand-sieving crawler-type excavator and loader

Beyond brute strength, the JG180LT excels through intelligent engineering. Crafted with reinforced chromium alloy screens and a vibration-optimized mechanism, it effortlessly processes wet, clay-heavy, or frozen materials that stall conventional equipment. The crawler base ensures unparalleled stability on steep gradients and soft subgrades, while intuitive controls empower crews to achieve uniform sieve quality with minimal training. By consolidating excavation, screening, and loading functions into one robust unit, it eradicates the need for auxiliary machinery—delivering up to 40% cost savings on labor, fuel, and equipment rentals while extending service life in corrosive coastal or desert environments.

Product Advantages

Technical Specifications

Application scenarios

Q&A

The JG180S Wheeled Railway Sleeper Changing Machine Railway Excavator is a revolutionary piece of equipment designed specifically for the railway construction and maintenance industry. With its advanced technology and robust design, it offers unparalleled efficiency and reliability in sleeper changing operations.

Read More

The JG150LT Railway Sleeper Changing Machine, a cutting - edge crawler railway excavator, is a game - changer in the realm of railway maintenance. Engineered to perfection, it offers a comprehensive solution for efficient and effective sleeper replacement operations.The crawler design of the JG150LT provides it with outstanding mobility on railway tracks. It can smoothly navigate through various terrains, including uneven surfaces and curves. This allows the machine to reach every part of the railway network, ensuring that no sleeper replacement task is out of reach. Whether it's a long - distance mainline or a short - stretch siding, the JG150LT can get the job done.

Read More

JG150LT15 ton track railway excavator railway single head tamping machine is a kind of efficient construction machinery designed for railway track maintenance, which integrates track mining and tamping functions in one. The equipment uses 15 tons of heavy chassis and modular structure design, equipped with intelligent hydraulic system and precise positioning module, can quickly complete the track ballast mining, ballast tamping under the pillow and track geometric parameter adjustment and other operations, the single head tamping device through high-frequency vibration and pressure control technology to achieve uniform compaction of the track bed, operating efficiency than traditional equipment increased by more than 30%.

Read More

JG150S is a high-performance multi-functional construction machine designed for modern railway track construction and maintenance. It integrates the functions of stamping, digging, track positioning and so on. It is suitable for laying, maintenance and repair of high-speed railway, general railway, subway and special track. The equipment adopts modular double-head design, carries intelligent control system, is compatible with all-weather complex working conditions, and is the core equipment to improve the efficiency of railway maintenance.

Read More

JG100SF ballast cleaning screen machine.Professional track cleaning solution! The integrated efficient screening system can quickly remove dirt and gravel impurities from the road bed, and the treatment capacity is up to 300m³/h. The modular design ADAPTS to the global standard gauge, and the automatic operation reduces the labor investment by 70%, which significantly improves the drainage and stability of the line. It is suitable for maintenance of heavy-duty railway, subway and high-speed line. The corrosion-resistant steel structure ensures the service life of more than 10 years.

Read More

Engineered for the demanding environments of railway construction and maintenance, the JG80LT 8-ton Crawler Excavator stands as your reliable partner on the tracks. Its robust crawler undercarriage provides exceptional stability and low ground pressure, crucial for navigating uneven ballast, soft shoulders, and confined spaces often encountered near rail lines. Equipped with a responsive hydraulic single bucket mechanism, this powerful machine delivers precise digging, trenching, and material handling capabilities, tackling everything from ballast renewal and drainage work to delicate trenching near sensitive infrastructure. Built compact yet powerful, the JG80LT excels where space is limited but performance cannot be compromised, ensuring your railway projects progress smoothly and efficiently.

Read More

The JG180LT redefines precision in rail infrastructure maintenance as a dedicated 18-ton crawler-type excavator and loader engineered for high-capacity sand and ballast sieving. Mounted directly on railway tracks, this powerhouse eliminates terrain limitations, enabling seamless material processing on active lines without disrupting schedules. Its integrated dual-function design allows operators to swiftly excavate, screen, and reload contaminants-free ballast in a single cycle—dramatically slashing project timelines while ensuring optimal track drainage and stability. Ideal for renewing aging corridors or upgrading high-speed routes, it transforms complex sieving operations into a mobile, self-sufficient workflow that meets the rigorous demands of global rail networks.

Read More

JG120S 12-ton wheeled rail excavator equipped with material leveler is an innovative construction machinery designed for coal leveling. It combines the dual functions of mining and leveling. It uses a 12-ton wheeled chassis to achieve fast switching between road and railway, carrying efficient hydraulic system and intelligent leveling module. It can accurately complete the mining, shaping and surface leveling tasks of coal pile to ensure the uniform distribution of materials and the efficiency of track maintenance. The compact and durable design of the whole machine is suitable for complex working conditions in coal mines, railway freight yards and industrial stations. The operating efficiency is increased by more than 25% compared with traditional equipment, while reducing manual intervention and operating costs. It is an ideal solution for modern material handling and track maintenance.

Read More