Custom Solutions For Track Maintance

JG180SF 18Ton Railroad Screen Machine Ballast Cleaning Machine Track Cleaner

The JG180SF Railroad Screen Machine pioneers next-generation railway maintenance with its integrated ballast cleaning and screening system. Engineered for extreme durability, it excels in harsh operational environments—from desert mining corridors to alpine transit routes—effortlessly separating contaminants while preserving reusable ballast integrity. Its adaptive screening mechanism dynamically adjusts to varying debris loads, ensuring uninterrupted workflow during track renewal projects. By automating critical processes like material filtration and waste extraction, the machine drastically reduces manual intervention, positioning it as an indispensable asset for modernizing global rail infrastructure with uncompromising efficiency.

Item No :

JG180SFOrder(MOQ) :

1Payment :

FOBProduct Origin :

ChinaColor :

yellow/ orange/ blueShipping Port :

xiamenLead Time :

15-45 daysWeight :

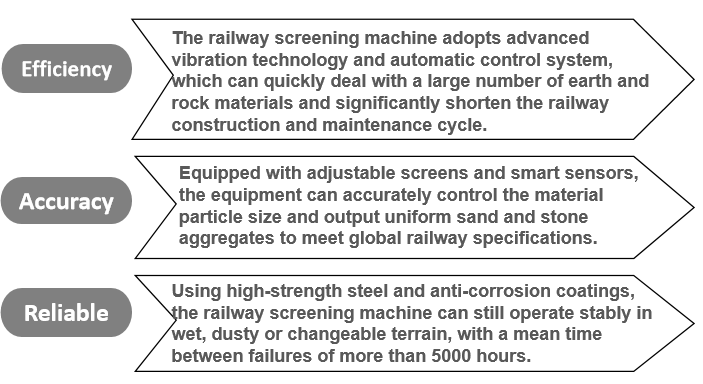

18000kgEfficiency,The railway screening machine adopts advanced vibration technology and automatic control system, which can quickly deal with a large number of earth and rock materials and significantly shorten the railway construction and maintenance cycle.Accuracy,Equipped with adjustable screens and smart sensors, the equipment can accurately control the material particle size and output uniform sand and stone aggregates to meet global railway specifications.Reliable,Using high-strength steel and anti-corrosion coatings, the railway screening machine can still operate stably in wet, dusty or changeable terrain, with a mean time between failures of more than 5000 hours.

|

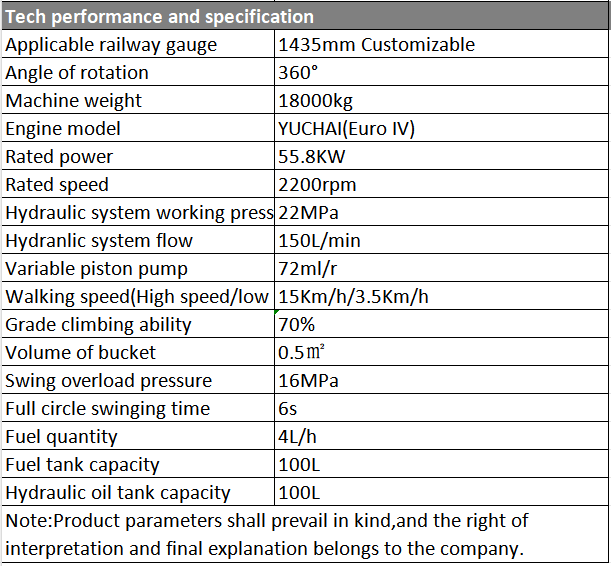

Tech performance and specification |

|

|

Applicable railway gauge |

1435mm Customizable |

|

Angle of rotation |

360° |

|

Machine weight |

18000kg |

|

Engine model |

YUCHAI(Euro IV) |

|

Rated power |

55.8KW |

|

Rated speed |

2200rpm |

|

Hydraulic system working pressure |

22MPa |

|

Hydranlic system flow |

150L/min |

|

Variable piston pump |

72ml/r |

|

Walking speed(High speed/low speed) |

15Km/h/3.5Km/h |

|

Grade climbing ability |

70% |

|

Volume of bucket |

0.5㎡ |

|

Swing overload pressure |

16MPa |

|

Full circle swinging time |

6s |

|

Fuel quantity |

4L/h |

|

Fuel tank capacity |

100L |

|

Hydraulic oil tank capacity |

100L |

|

Note:Product parameters shall prevail in kind,and the right of interpretation and final explanation belongs to the company. |

|

Product Overview

JG180SF 18Ton Railroad Screen Machine Ballast Cleaning Machine Track Cleaner

Redefining eco-efficiency in rail operations, the JG180SF champions sustainable resource management through closed-loop ballast rehabilitation. Its intelligent contamination control system minimizes environmental footprint by diverting waste from landfills and maximizing material reuse. Operators benefit from modular design flexibility, enabling rapid reconfiguration for diverse scenarios—emergency landslide clearance, coastal route corrosion mitigation, or high-frequency passenger line upkeep. This versatility, combined with ergonomic safety features and reduced lifecycle costs, empowers contractors and national rail agencies to achieve stringent compliance standards while future-proofing critical transportation networks.

Product Advantages

Technical Specifications

Application scenarios

Global Exhibition

In response to the demands of customers from different regions, the company participates in internationally renowned industry exhibitions every year. Our products are exported to over 60 countries and regions in Central Asia, Southeast Asia, the Middle East, South America, Africa, Oceania and so on. The annual export volume reaches more than 1,500 units and we enjoy a high reputation in overseas markets. Every appearance showcases the brand's global influence. We join hands with our partners to win the future together!

About Us

Quanzhou Jingong Machinery Equipment Co., Ltd. is equipped with various imported large-scale processing equipment, professional technical developers and outstanding management talents. As a global construction machinery manufacturing enterprise integrating R&D, production, sales and service, it provides high-performance and highly reliable construction machinery equipment and intelligent solutions for customers worldwide. The annual sales exceed 30 to 50 million US dollars, and the annual production of excavators can reach about 2,000 to 3,000 units.

Credential

The company has passed the ISO9001 quality management system certification and the national intellectual property certification, and holds nearly a hundred patent certificates including invention patents, design patents and utility model patents. It has been awarded titles such as "Well-known Domestic Trademark" and "National High-tech Enterprise", and has received numerous honors. It has simultaneously won multiple international and domestic invention gold awards and has the right to export independently.

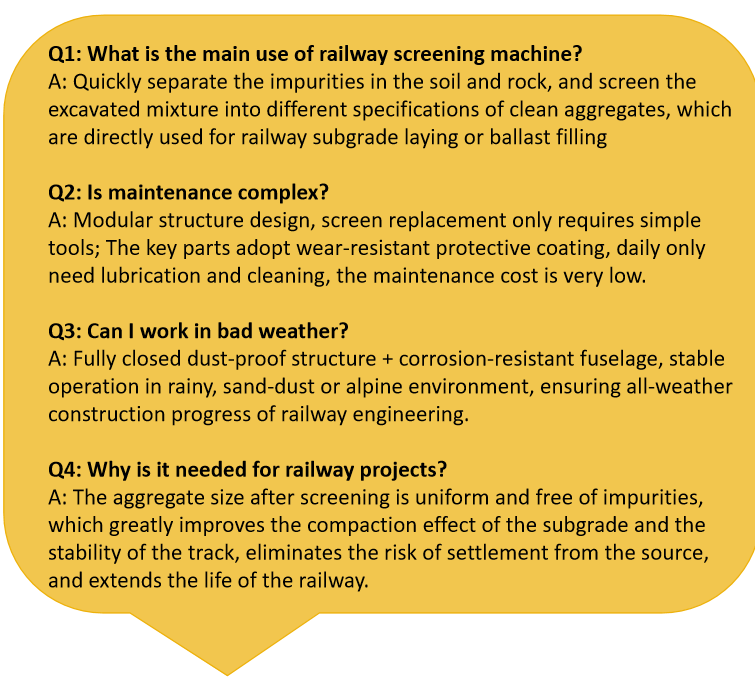

Q&A