Custom Solutions For Track Maintance

The Double Tamping Ballast Head For Railway Maintenance Excavators is a core operation accessory specifically designed to enhance the efficiency and quality of railway track bed maintenance. This tamping head features an innovative dual-head parallel tamping structure, which can simultaneously apply force to the ballast areas beneath two sleepers. Through powerful hydraulic vibration and controllable downward pressure, it quickly compresses loose ballast particles into the bottom of the sleeper and the sleeper box, achieving an immediate and uniform consolidation effect of the track bed, effectively restoring the designed elevation and geometric stability of the track.

Item No :

JG-LTOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

blackShipping Port :

XiamenLead Time :

15-45daysWeight :

700kg

|

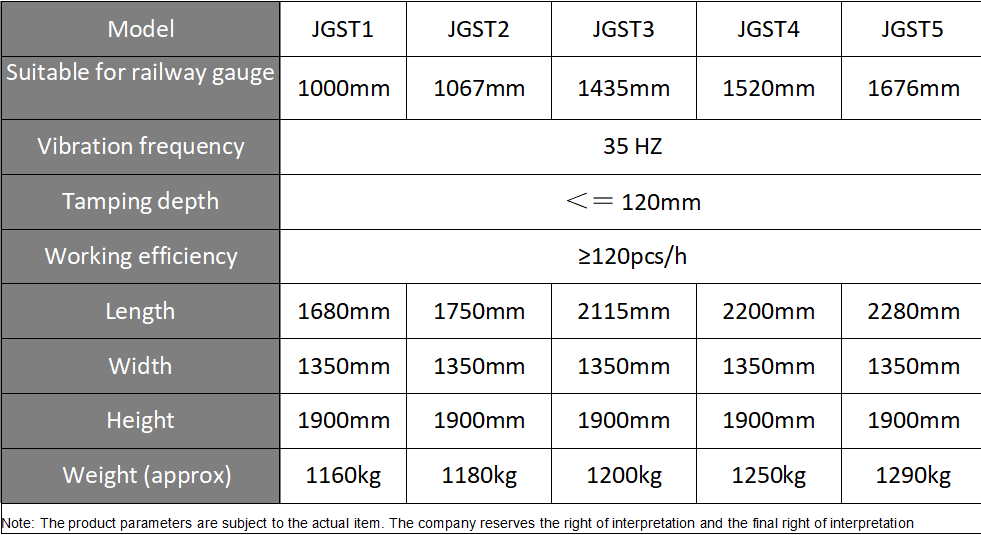

Model |

JGST1 |

JGST2 |

JGST3 |

JGST4 |

JGST5 |

|

Suitable for railway gauge

|

1000mm |

1067mm |

1435mm |

1520mm |

1676mm |

|

Vibration frequency |

35 HZ |

||||

|

Tamping depth |

<= 120mm |

||||

|

Working efficiency |

≥120pcs/h |

||||

|

Length |

1680mm |

1750mm |

2115mm |

2200mm |

2280mm |

|

Width |

1350mm |

1350mm |

1350mm |

1350mm |

1350mm |

|

Height |

1900mm |

1900mm |

1900mm |

1900mm |

1900mm |

|

Weight (approx) |

1160kg |

1180kg |

1200kg |

1250kg |

1290kg |

|

Note: The product parameters are subject to the actual item. The company reserves the right of interpretation and the final right of interpretation |

|||||

Product Overview

Double Tamping Ballast Head For Railway Maintenance Excavators

Double Tamping Ballast Head for Railway Maintenance Excavators The core components of this product are forged from special wear-resistant alloy steel, featuring outstanding shock resistance and fatigue resistance, perfectly adapting to the harsh working conditions of sharp and highly abrasive ballast; the modular quick-change interface design ensures its seamless compatibility with mainstream railway maintenance excavators, enabling quick switching between excavation and tamping functions, and is particularly suitable for efficient and continuous line fine-tuning operations within the track limit. The unique amplitude and frequency adjustment function can be optimized for different types of ballast (such as granite and basalt) and tamping requirements, ensuring consistent tamping depth and uniform force, minimizing disturbance to the existing track bed structure, and significantly improving the smoothness and bearing capacity of the line after tamping. This double-head tamping head is an ideal solution for achieving precise, fast, and low-interference track bed maintenance in modern railway maintenance, ensuring safe operation and extending maintenance cycles.

Technical Specifications

Customizable

In the complex scene of railway construction and maintenance, standardized assistive devices are often difficult to meet diverse needs. We offer full-process customized accessory solutions, from breaking hammers and hydraulic rammers to rail tie installers. Each product can be redesigned according to your equipment model, operating environment and special functional requirements.

Application Scenarios

Global Exhibition

In response to the demands of customers from different regions, the company participates in internationally renowned industry exhibitions every year. Our products are exported to over 60 countries and regions in Central Asia, Southeast Asia, the Middle East, South America, Africa, Oceania and so on. The annual export volume reaches more than 1,500 units and we enjoy a high reputation in overseas markets. Every appearance showcases the brand's global influence. We join hands with our partners to win the future together!

About Us

Quanzhou Jingong Machinery Equipment Co., Ltd. is equipped with various imported large-scale processing equipment, professional technical developers and outstanding management talents. As a global construction machinery manufacturing enterprise integrating R&D, production, sales and service, it provides high-performance and highly reliable construction machinery equipment and intelligent solutions for customers worldwide. The annual sales exceed 30 to 50 million US dollars, and the annual production of excavators can reach about 2,000 to 3,000 units.

Credential

The company has passed the ISO9001 quality management system certification and the national intellectual property certification, and holds nearly a hundred patent certificates including invention patents, design patents and utility model patents. It has been awarded titles such as "Well-known Domestic Trademark" and "National High-tech Enterprise", and has received numerous honors. It has simultaneously won multiple international and domestic invention gold awards and has the right to export independently.

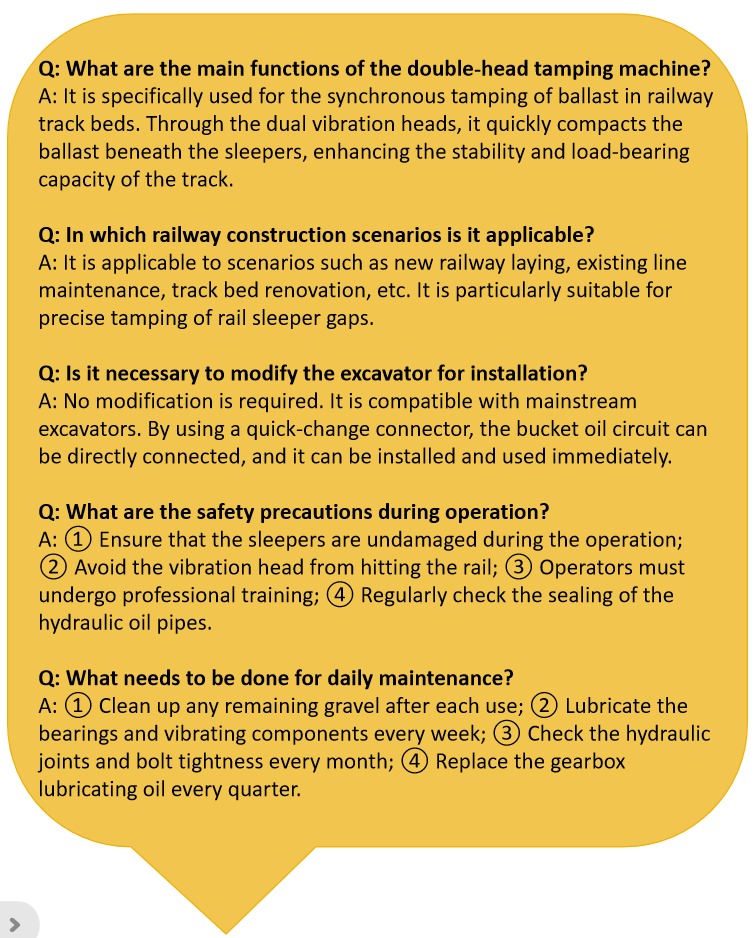

Q&A