Custom Solutions For Track Maintance

The JG150LT railway sand-sieving bucket redefines efficiency for 15-ton crawler excavators in rail infrastructure projects. Engineered to tackle demanding ballast and sand screening tasks, this attachment seamlessly integrates with standard excavators to deliver precision-grade material separation directly on-site. Its robust bucket design eliminates the need for secondary processing equipment, allowing operators to sieve contaminants, rejuvenate track ballast, and restore optimal drainage in a single pass. Ideal for high-traffic corridors or remote sidings, it minimizes operational downtime while enhancing track stability and longevity—transforming routine maintenance into a swift, cost-effective process that meets the rigorous demands of modern railways.

Item No :

JG150LTOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

yellowShipping Port :

xiamenLead Time :

15-45daysWeight :

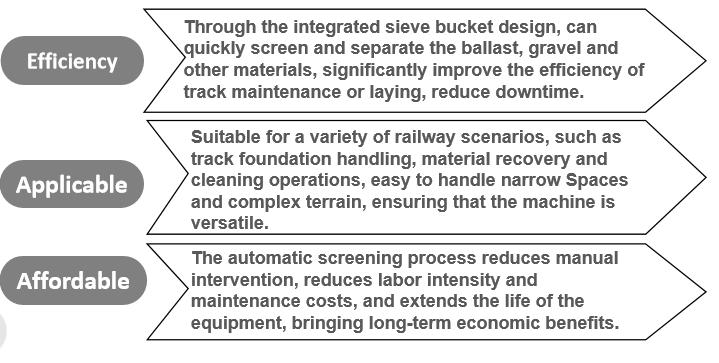

15000kgThrough the integrated sieve bucket design, can quickly screen and separate the ballast, gravel and other materials, significantly improve the efficiency of track maintenance or laying, reduce downtime.Suitable for a variety of railway scenarios, such as track foundation handling, material recovery and cleaning operations, easy to handle narrow Spaces and complex terrain, ensuring that the machine is versatile.The automatic screening process reduces manual intervention, reduces labor intensity and maintenance costs, and extends the life of the equipment, bringing long-term economic benefits.

|

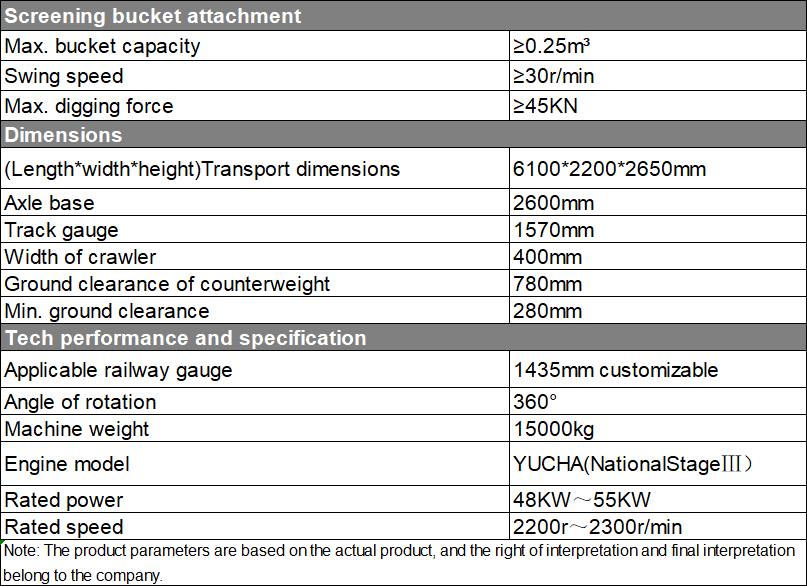

Screening bucket attachment |

|

|

Max. bucket capacity |

≥0.25m³ |

|

Swing speed |

≥30r/min |

|

Max. digging force |

≥45KN |

|

Dimensions |

|

|

(Length*width*height)Transport dimensions |

6100*2200*2650mm |

|

Axle base |

2600mm |

|

Track gauge |

1570mm |

|

Width of crawler |

400mm |

|

Ground clearance of counterweight |

780mm |

|

Min. ground clearance |

280mm |

|

Tech performance and specification |

|

|

Applicable railway gauge |

1435mm customizable |

|

Angle of rotation |

360° |

|

Machine weight |

15000kg |

|

Engine model |

YUCHA(NationalStageⅢ) |

|

Rated power |

48KW~55KW |

|

Rated speed |

2200r~2300r/min |

|

Note: The product parameters are based on the actual product, and the right of interpretation and final interpretation belong to the company. |

|

Product Overview

JG150LT 15-ton railway sand-sieving bucket crawler excavator

Beyond raw power, the JG150LT excels with intelligent engineering focused on durability and operator ease. Crafted from abrasion-resistant alloys and featuring a dynamic screening mechanism, it effortlessly handles wet, compacted, or uneven material without clogging. The intuitive design requires minimal training, enabling crews to achieve uniform sieve results across diverse terrains—from coastal lines to desert crossings. By reducing manual labor and machinery dependency, it not only accelerates project timelines but also slashes long-term maintenance costs, making it an indispensable asset for global rail contractors prioritizing sustainability and operational excellence.

Product Advantages

Technical Specifications

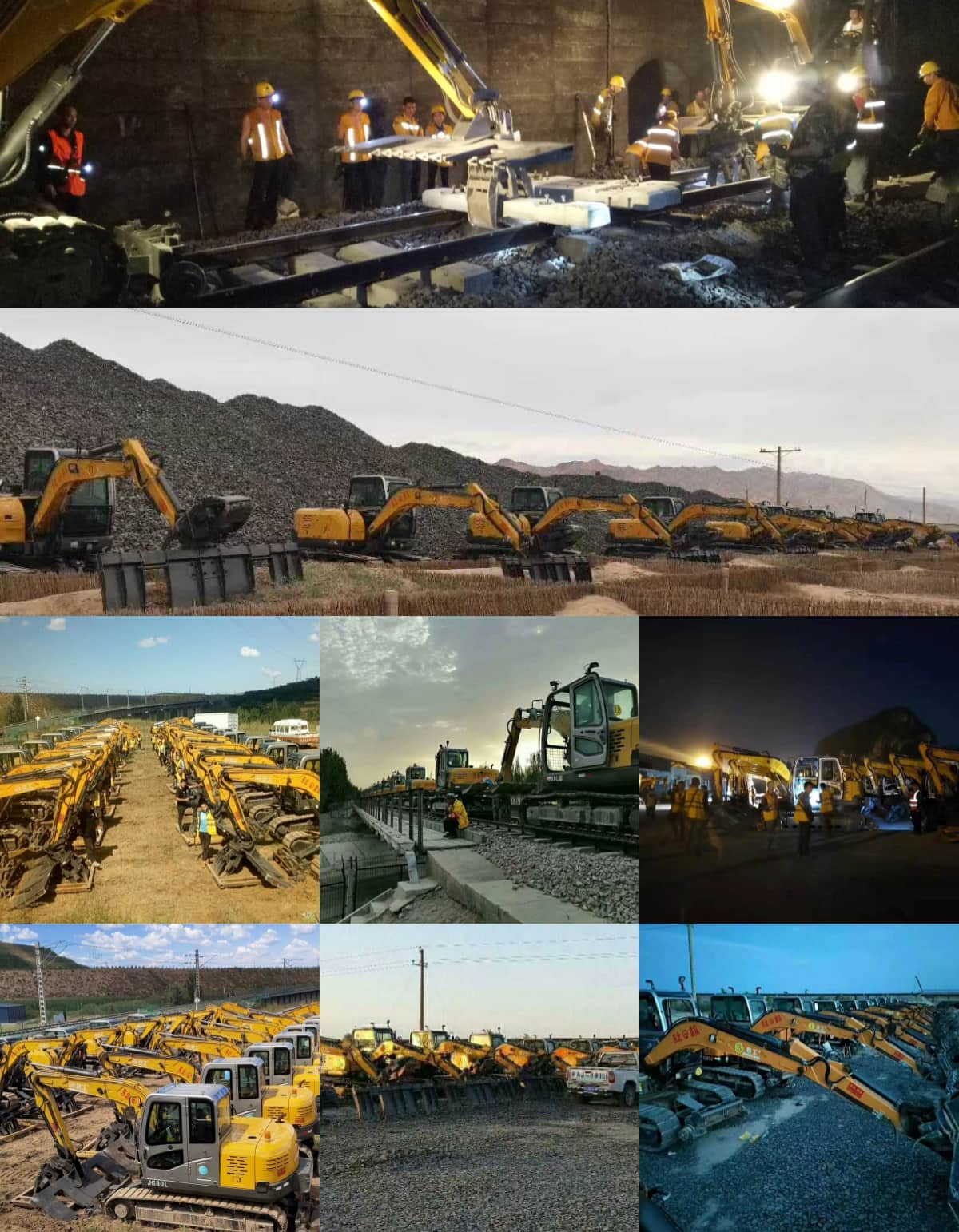

Application scenarios

Global Exhibition

In response to the demands of customers from different regions, the company participates in internationally renowned industry exhibitions every year. Our products are exported to over 60 countries and regions in Central Asia, Southeast Asia, the Middle East, South America, Africa, Oceania and so on. The annual export volume reaches more than 1,500 units and we enjoy a high reputation in overseas markets. Every appearance showcases the brand's global influence. We join hands with our partners to win the future together!

About Us

Quanzhou Jingong Machinery Equipment Co., Ltd. is equipped with various imported large-scale processing equipment, professional technical developers and outstanding management talents. As a global construction machinery manufacturing enterprise integrating R&D, production, sales and service, it provides high-performance and highly reliable construction machinery equipment and intelligent solutions for customers worldwide. The annual sales exceed 30 to 50 million US dollars, and the annual production of excavators can reach about 2,000 to 3,000 units.

Credential

The company has passed the ISO9001 quality management system certification and the national intellectual property certification, and holds nearly a hundred patent certificates including invention patents, design patents and utility model patents. It has been awarded titles such as "Well-known Domestic Trademark" and "National High-tech Enterprise", and has received numerous honors. It has simultaneously won multiple international and domestic invention gold awards and has the right to export independently.

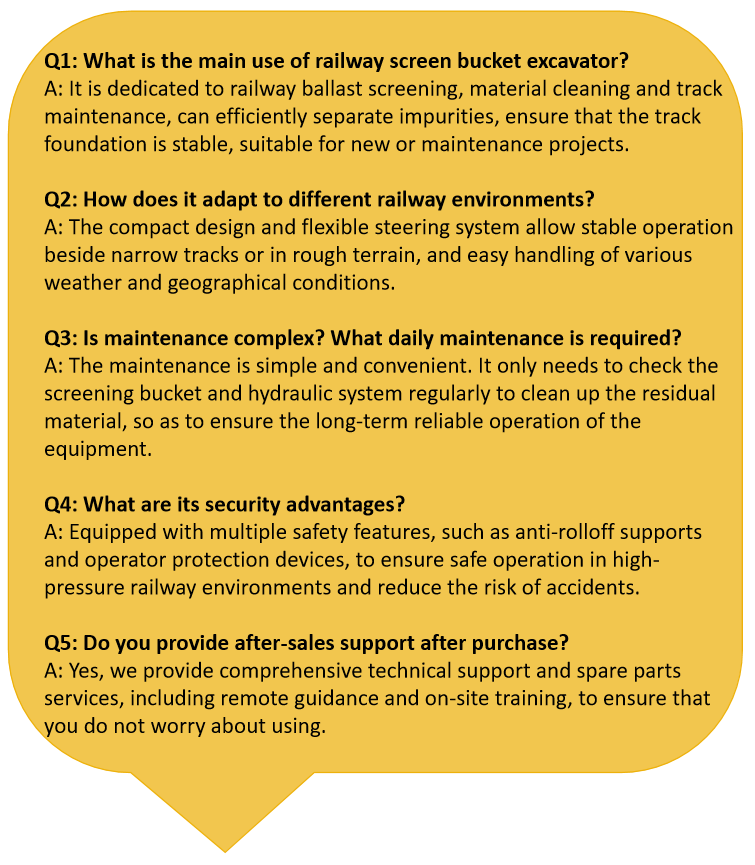

Q&A