Custom Solutions For Track Maintance

Designed specifically to enhance the accuracy and efficiency of railway track maintenance, the adjustable dual tamping head auxiliary device has completely revolutionized the ballast tamping process through its innovative dual-head synchronous operation mode. Its core advantage lies in the fully adjustable dual tamping heads, which allow the operator to flexibly and independently adjust the entry angle, downward pressure depth and tamping strength of each tamping head according to the type of sleeper, ballast distribution and track geometric conditions, achieving precise operation to the millimeter level. This device can seamlessly adapt to manual or semi-automated work processes, with mechanical assistance significantly reducing the manual operation load, while ensuring uniform and high-density tamping of the ballast beneath both sides of the sleepers, significantly improving the stability and operational safety of the track structure. Whether dealing with standard ballast stones in straight sections or special gradations in curved sections, its outstanding adaptability to various working conditions makes it a key technical equipment for extending the lifespan of the track and ensuring the smooth operation of trains.

Item No :

JG-LTOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

black or yellowShipping Port :

XiamenLead Time :

15-45daysWeight :

1110kg

|

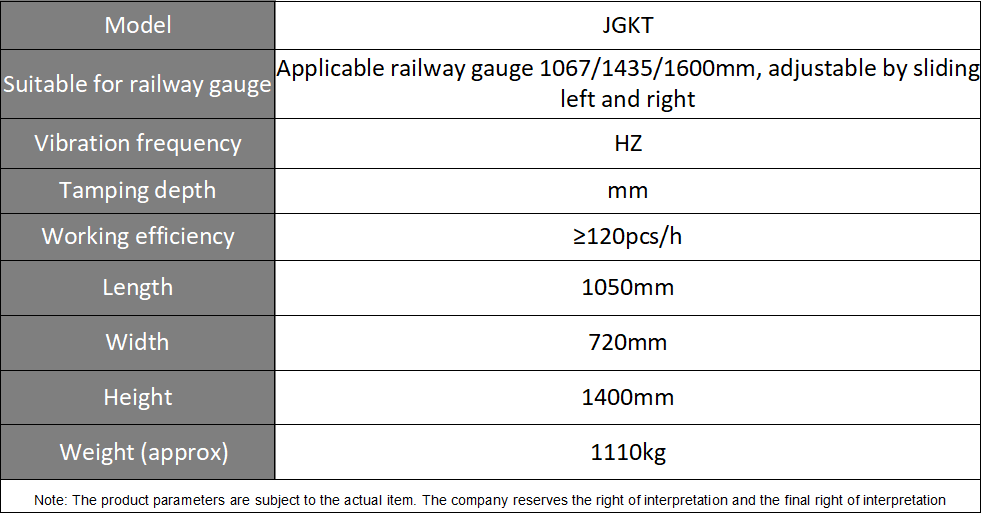

Model |

JGST1 |

JGST2 |

JGST3 |

JGST4 |

JGST5 |

|

Suitable for railway gauge

|

1000mm |

1067mm |

1435mm |

1520mm |

1676mm |

|

Vibration frequency |

35 HZ |

||||

|

Tamping depth |

<= 120mm |

||||

|

Working efficiency |

≥120pcs/h |

||||

|

Length |

1680mm |

1750mm |

2115mm |

2200mm |

2280mm |

|

Width |

1350mm |

1350mm |

1350mm |

1350mm |

1350mm |

|

Height |

1900mm |

1900mm |

1900mm |

1900mm |

1900mm |

|

Weight (approx) |

1160kg |

1180kg |

1200kg |

1250kg |

1290kg |

|

Note: The product parameters are subject to the actual item. The company reserves the right of interpretation and the final right of interpretation |

|||||

Product Overview

Adjustable Double Tamping Ballast Head Assistive Devices

Under the complex and variable track conditions, this device demonstrates revolutionary advantages through its intelligent feedback regulation system and millimeter-level dynamic compensation mechanism - when irregularities in the sleeper gap or differences in ballast density are detected, its bidirectional hydraulic drive module can adjust the force balance of the dual tamping heads in real time, completely eliminating the risk of track skew caused by traditional single-point operations; especially when dealing with the super elevation transition zone of curved sections, the ±15° adaptive inclination function enables the tamping head to always enter the ballast layer perpendicularly, avoiding damage to the ballast or sleeper caused by angle deviation. More groundbreaking is the non-disassembly adjustment design: the operator can complete the rapid mode switching from wide-gauge heavy-haul railways to narrow-gauge mining lines through the integrated control panel alone, significantly reducing the equipment transfer time. This innovation that integrates precise mechanical control, condition self-adaptability, and ergonomic optimization has not only raised the qualification rate of track geometric dimensions to a new level, but also promoted railway maintenance from empirical and extensive operations to data-driven preventive maintenance, providing the underlying technical support for building a smart track operation network.

Technical Specifications

Customizable

In the complex scene of railway construction and maintenance, standardized assistive devices are often difficult to meet diverse needs. We offer full-process customized accessory solutions, from breaking hammers and hydraulic rammers to rail tie installers. Each product can be redesigned according to your equipment model, operating environment and special functional requirements.

Application Scenarios

Global Exhibition

In response to the demands of customers from different regions, the company participates in internationally renowned industry exhibitions every year. Our products are exported to over 60 countries and regions in Central Asia, Southeast Asia, the Middle East, South America, Africa, Oceania and so on. The annual export volume reaches more than 1,500 units and we enjoy a high reputation in overseas markets. Every appearance showcases the brand's global influence. We join hands with our partners to win the future together!

About Us

Quanzhou Jingong Machinery Equipment Co., Ltd. is equipped with various imported large-scale processing equipment, professional technical developers and outstanding management talents. As a global construction machinery manufacturing enterprise integrating R&D, production, sales and service, it provides high-performance and highly reliable construction machinery equipment and intelligent solutions for customers worldwide. The annual sales exceed 30 to 50 million US dollars, and the annual production of excavators can reach about 2,000 to 3,000 units.

Credential

The company has passed the ISO9001 quality management system certification and the national intellectual property certification, and holds nearly a hundred patent certificates including invention patents, design patents and utility model patents. It has been awarded titles such as "Well-known Domestic Trademark" and "National High-tech Enterprise", and has received numerous honors. It has simultaneously won multiple international and domestic invention gold awards and has the right to export independently.

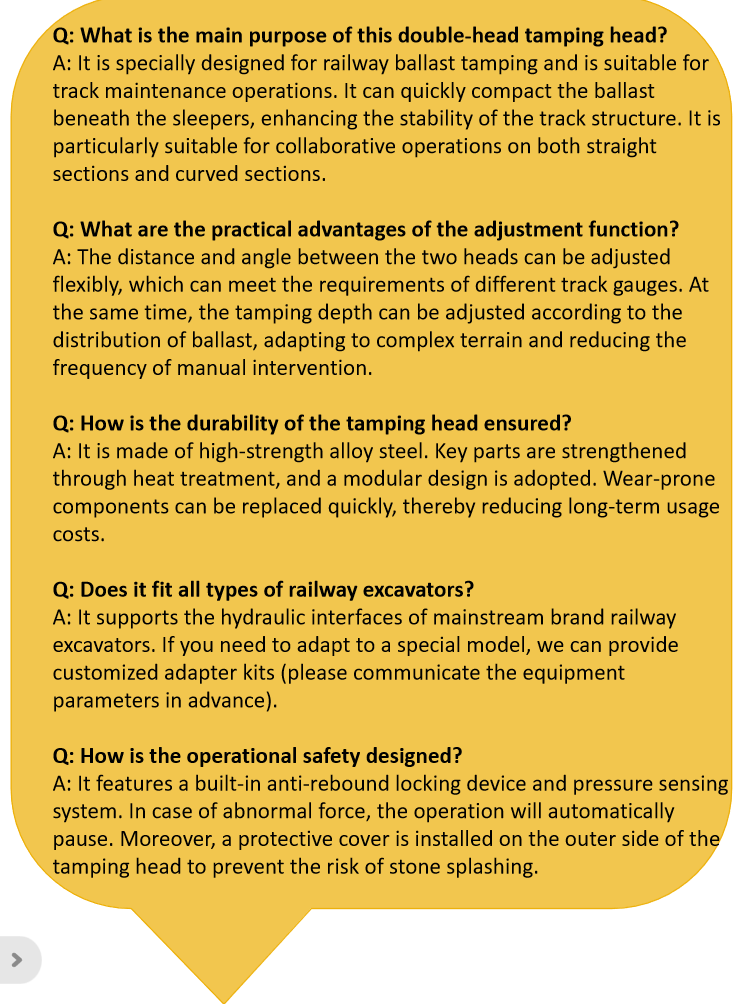

Q&A