Custom Solutions For Track Maintance

Revolutionize track maintenance efficiency with the JG Hydraulic Guide Rail Gripper – the ultimate excavator-mounted solution for safe and precise rail handling. Designed specifically for railway construction and track renewal projects, this robust hydraulic rail gripper transforms standard railway excavators into versatile rail handling machines. Its industry-leading clamping force and anti-slip teeth ensure secure lifting of UIC54/60 rails during rail replacement, switch installation, or emergency repairs. Eliminate crane dependency and manual labor risks while maintaining track alignment accuracy in confined rail corridors or tunnel work zones.

Item No :

JGDJOrder(MOQ) :

1Payment :

L/C or T/TProduct Origin :

ChinaColor :

blackShipping Port :

XiamenLead Time :

15-45daysWeight :

475kg|

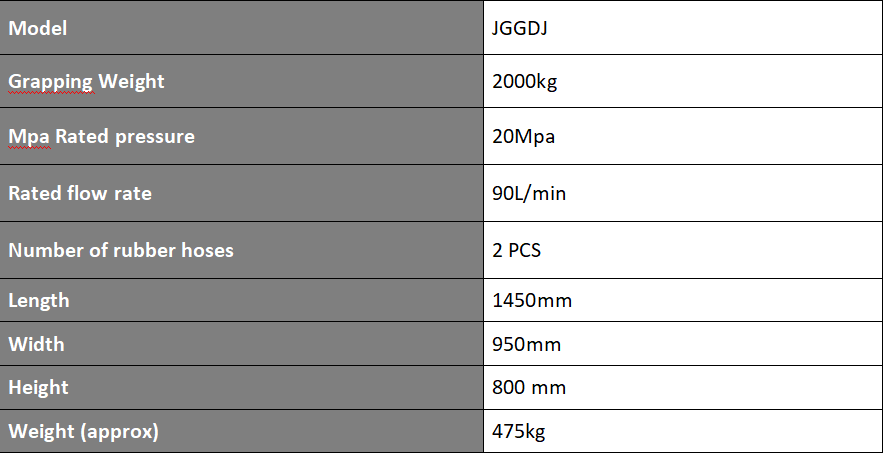

Model |

JGGDJ |

|

Grapping Weight |

2000kg |

|

Mpa Rated pressure |

20Mpa |

|

Rated flow rate |

90L/min |

|

Number of rubber hoses |

2 PCS |

|

Length |

1450mm |

|

Width |

950mm |

|

Height |

800 mm |

|

Weight (approx) |

475kg |

Product Overview

JG hydraulic guide rail gripper railway excavator

Unlock unparalleled operational agility in rail infrastructure projects through the JG Gripper's advanced engineering. Featuring 360° hydraulic rotation and load-sensing valves, this excavator rail attachment enables millimeter-precision positioning of rails across complex terrains – from rail embankments to bridge approaches. The integrated safety interlock system prevents accidental drops, while quick-coupler compatibility allows rapid deployment across your rail maintenance fleet. Maximize asset utilization and slash project timelines for railway construction crews, track laying teams, and infrastructure contractors with this indispensable heavy-duty rail manipulator.

Technical Specifications

Customizable

In the complex scene of railway construction and maintenance, standardized assistive devices are often difficult to meet diverse needs. We offer full-process customized accessory solutions, from breaking hammers and hydraulic rammers to rail tie installers. Each product can be redesigned according to your equipment model, operating environment and special functional requirements.

Application Scenarios

Global Exhibition

In response to the demands of customers from different regions, the company participates in internationally renowned industry exhibitions every year. Our products are exported to over 60 countries and regions in Central Asia, Southeast Asia, the Middle East, South America, Africa, Oceania and so on. The annual export volume reaches more than 1,500 units and we enjoy a high reputation in overseas markets. Every appearance showcases the brand's global influence. We join hands with our partners to win the future together!

About Us

Quanzhou Jingong Machinery Equipment Co., Ltd. is equipped with various imported large-scale processing equipment, professional technical developers and outstanding management talents. As a global construction machinery manufacturing enterprise integrating R&D, production, sales and service, it provides high-performance and highly reliable construction machinery equipment and intelligent solutions for customers worldwide. The annual sales exceed 30 to 50 million US dollars, and the annual production of excavators can reach about 2,000 to 3,000 units.

Credential

The company has passed the ISO9001 quality management system certification and the national intellectual property certification, and holds nearly a hundred patent certificates including invention patents, design patents and utility model patents. It has been awarded titles such as "Well-known Domestic Trademark" and "National High-tech Enterprise", and has received numerous honors. It has simultaneously won multiple international and domestic invention gold awards and has the right to export independently.

Q&A

The JG Railway Sleeper Changing Machine's Sleeper Changer Head is a core component specially developed for railway sleeper replacement projects. It is designed with a precise structure and made of high-strength and wear-resistant materials. It can be adapted to various railway maintenance scenarios and efficiently completes tasks such as sleeper positioning, clamping, and replacement. Its modular design supports rapid installation and flexible adjustment, meeting the requirements of different track gauges and sleeper specifications. At the same time, through the integration of an automated operation module, it ensures seamless cooperation with the sleeper replacement equipment, improving the operation efficiency and significantly shortening the construction period. The intelligent protection mechanism effectively avoids accidental damage to the track sub-base during construction, ensuring the precise restoration of the line's geometric parameters, and providing a safe and reliable, low-maintenance-cost sleeper update solution for the railway maintenance team.

Read More

The Screening Bucket is a revolutionary accessory specifically designed for the precise material handling requirements in railway construction and maintenance. It is seamlessly integrated into the track-specific excavators. In narrow track areas or on the roadbed operation space, with its efficient vibrating screening mechanism, it can directly perform on-site instantaneous classification processing of the excavated soil, crushed stones, or recycled ballast - separating out the clean aggregates that meet the specifications for direct backfill and reuse, while simultaneously removing oversized stones, debris, and fine particle waste, significantly optimizing the material management process.

Read More

The Double Tamping Ballast Head For Railway Maintenance Excavators is a core operation accessory specifically designed to enhance the efficiency and quality of railway track bed maintenance. This tamping head features an innovative dual-head parallel tamping structure, which can simultaneously apply force to the ballast areas beneath two sleepers. Through powerful hydraulic vibration and controllable downward pressure, it quickly compresses loose ballast particles into the bottom of the sleeper and the sleeper box, achieving an immediate and uniform consolidation effect of the track bed, effectively restoring the designed elevation and geometric stability of the track.

Read More

The Single Tamping Ballast Head For Railway Excavators is a core operation accessory specifically designed to enhance the efficiency and accuracy of railway track bed maintenance. This tamping head is integrated at the front end of a track-specific excavator. With its high-strength alloy steel forged core tamping arm and precisely designed tamping head, it can precisely insert into the sleeper box area, apply deep vibration and controllable downward pressure to the loose ballast, efficiently achieve the compact filling and uniform compaction of ballast at the sleeper bottom and shoulder, and quickly restore the support stiffness of the track bed and the geometric stability of the track.

Read More

The JG Material Leveling Device Accessories are a dedicated set of components specifically designed for the precise maintenance of railway track beds and subgrades. They strictly adhere to the design specifications and interface standards of JG brand core operation equipment, and can be easily integrated into the mainframe platforms (such as tamping vehicles, maintenance excavators, or specialized leveling equipment) to achieve millimeter-level leveling accuracy and preset slope control for ballast, sub-ballast, and roadbed fill materials. The accessory package includes high-strength alloy wear-resistant scrapers, adjustable angle adjustment frames, intelligent sensing feedback modules, and quick locking mechanisms, ensuring efficient leveling of loose materials between sleepers, rail shoulders, and roadbed surfaces in complex conditions, eliminating local unevenness.

Read More

The Railway Machine Sleeper Changer Head (with Digging Bucket) is a revolutionary multi-functional attachment specially designed for efficient and precise maintenance of modern railways. It innovatively integrates a powerful digging capability with a precise sleeper replacement function, enabling a single railway construction machine to complete the entire process of removing old sleepers, local track bed tidying, and precise installation of new sleepers within the narrow space within the railway track limit. Its core is forged from ultra-high-strength special alloy steel, featuring outstanding impact resistance and wear resistance, and can easily handle the long-term wear caused by the sharp edges of ballast.

Read More

The Standard Railway Excavator Bucket is specifically designed for railway construction and maintenance tasks, offering outstanding durability and efficient operation performance. Its sturdy structure is made of high-strength steel, perfectly adapting to demanding environments such as track excavation, ground leveling, and material handling, effectively resisting wear and impact.

Read More

Railway Machine Sleeper Grab Applicable to All Railway Tracks is a universal track sleeper grasping device specially designed for efficient maintenance of all types of railway tracks. It innovatively integrates a high-strength alloy structure, adaptive clamping technology, and an intelligent control module, enabling it to precisely adapt to the requirements of sleeper replacement in various global rail gauges, sleeper specifications, and line environments (such as high-speed railways, heavy-load freight lines, urban light rail, etc.). This device adopts a modular quick-change interface design, which can be seamlessly integrated into the front end of various railway construction machinery. With its multi-directionally adjustable hydraulic clamps and pressure sensing system, it can not only stably grasp various types of sleepers made of wood, concrete, or composite materials, but also intelligently adjust the clamping force according to the sleeper embedding depth and track bed condition, ensuring a fully non-destructive operation from safely extracting old sleepers to accurately inserting new ones.

Read More